When a toxic gas leak forced the evacuation of an entire factory—and sent three employees to the ER—it wasn’t the lack of safety equipment that was to blame. It was a broken risk management process. The warning signs were there. The procedures were on paper. But no one saw them in time.

That’s the real danger: not what you don’t know, but what you think you’ve already handled.

EHS risk management is no longer just a regulatory box to tick—it’s the frontline system for protecting people, preventing costly shutdowns, and keeping your business resilient in a high-risk world. Consider this: U.S. private industry alone reported 2.6 million nonfatal workplace injuries and illnesses in 2023—a stark reminder that risks are everywhere, not going away.

In this guide, we’ll unpack what EHS risk management actually involves—from identifying and scoring risks to assigning corrective actions and tracking results. You’ll learn how it differs from a basic risk assessment, which types of threats to watch, and how to build a system that’s not only compliant but capable of scaling across dynamic, multi-site operations.

We’ll also show how modern platforms like Field1st are helping leading teams ditch the spreadsheets and clipboards, and run safety like they run the rest of the business: in real time, with full visibility, and from the field up.

What is EHS Risk Management?

Environmental Health and Safety (EHS) Risk Management is the ongoing, dynamic process of identifying, evaluating, mitigating, and continuously monitoring the environmental, health, and safety threats that can harm your people, operations, and the environment. It’s not a once-a-year audit or a binder of procedures—it’s a living, breathing framework that drives daily decisions.

At its core, EHS risk management is about anticipation. It’s what allows a safety officer to flag a faulty valve before it causes a leak. It’s how a foreman can spot heat stress signs before a worker collapses. And it’s how executives stay ahead of compliance before a surprise inspection shows up at the gate.

It covers everything—from chemical storage to air quality, machine hazards to ergonomic strain. When done right, it gives you real visibility into what could go wrong—and the power to stop it before it does.

Without it, you’re gambling with downtime, fines, and lives. With it, safety becomes a strategic advantage.

What is EHS Risk Assessment?

EHS Risk Assessment is the backbone of every effective risk management strategy. It’s the evaluation phase—where potential threats are not only spotted, but sized up. It’s how your team determines whether that leaking valve is a minor maintenance issue or a full-blown evacuation risk.

This process involves systematically identifying hazards, analyzing the likelihood of each occurring, assessing the severity of their potential impact, and prioritizing actions to control or eliminate them. From high-decibel machinery to volatile chemicals and repetitive motion injuries, risk assessments help teams make informed, proactive decisions.

Many confuse risk management with risk assessment, but here’s the catch: risk assessment is just one chapter in the bigger story. If EHS Risk Management is the full-length feature film, risk assessment is that critical scene where the stakes become real and the action starts. It sets the tone—but it’s not the endgame.

A complete EHS program doesn’t stop with evaluation. It uses risk assessments as a launchpad for implementation, real-time tracking, post-incident reviews, and ongoing optimization.

Why Environmental Health Safety Risk Management Matters

Whether you’re running a high-pressure refinery, a multi-acre construction site, or a remote wind farm in the desert, one truth remains: risk never sleeps. Environmental Health and Safety (EHS) Risk Management isn’t a formality—it’s your frontline defense against chaos.

EHS risk management is both protective and it’s profitable. It secures your workforce, safeguards the communities around you, and stabilizes operations in an increasingly unpredictable world. Here’s how:

Avoid Catastrophic Events:

Fires, chemical spills, electrical failures, falls from height—these aren’t rare flukes. They’re the predictable result of unmanaged risk. A strong EHS program identifies the red flags before they spark into disaster.

Ensure Compliance:

Regulatory bodies like OSHA, the EPA, and regional safety authorities don’t wait for you to get it right. Failing an audit can mean heavy fines, shutdowns, or even criminal charges. A proactive EHS system keeps your sites inspection-ready 24/7.

Protect Workers and Communities:

It’s not just about your employees. Your safety footprint extends to subcontractors, nearby neighborhoods, and the environment. EHS management ensures that no one becomes collateral damage from poor planning or missing processes.

Reduce Costs and Insurance Premiums:

Every incident avoided is money saved—on medical claims, downtime, legal exposure, and insurance premiums. Fewer accidents mean leaner operations and a more resilient bottom line.

Enable Sustainable Operations:

EHS is a pillar of long-term sustainability. When you build risk management into your ESG framework, you future-proof your business against regulatory shifts, climate challenges, and reputational risks.

Modern digital tools bring all of this into reach. Rather than layering another software on top of the chaos, they can replace outdated, paper-based processes with mobile, real-time systems that connect your crews, capture your risks, and close the loop on every action before things go wrong.

Types of EHS Risk

You can’t manage what you don’t understand—and in Environmental Health and Safety, risks come in many forms. From the obvious to the invisible, each type carries the potential to halt operations, hurt workers, and hammer your bottom line. Understanding risk types is key to managing them effectively. Here’s a breakdown of the major EHS risk categories—and why they matter:

Physical Risks:

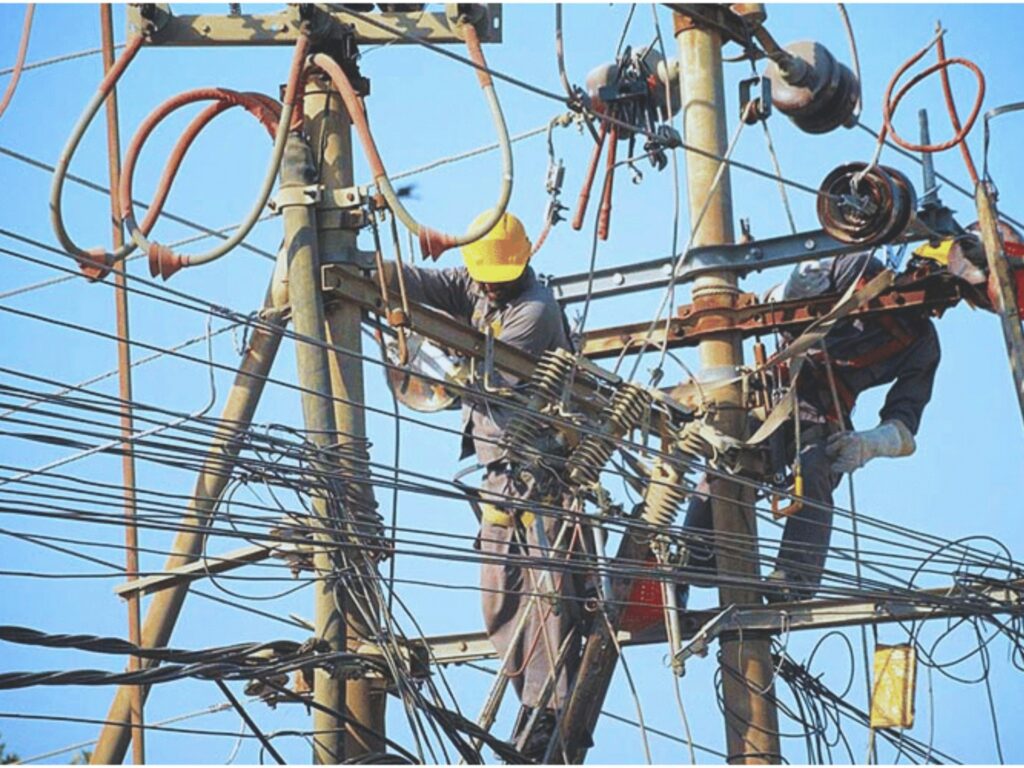

These are the frontline threats—think unguarded machines, moving parts, high-voltage gear, extreme temperatures, slippery surfaces, and heights without protection. If you can see it, hear it, or trip over it, it’s a physical risk. These are the kinds of hazards that send workers to the ER and cost companies millions in lost time and liability.

Chemical Risks:

It only takes one missed label or improperly sealed drum to turn a safe jobsite into a hazmat zone. Flammable vapors, corrosive substances, leaking gases—chemical risks demand constant attention and tight protocols.

Biological Risks:

Often underestimated, these include exposure to viruses, bacteria, mold, and contaminated materials. In food production, waste management, or healthcare-adjacent fields, these risks can spread fast and silently, triggering health issues and regulatory violations.

Ergonomic Risks:

Long-term injuries start with small, repeated movements. Poor lifting posture, awkward tool positions, improperly adjusted workstations—these risks slowly eat into workforce health and productivity. Capturing them requires regular feedback from the field—not just desk-bound assessments.

Environmental Risks:

These aren’t just about compliance—they’re existential. Oil leaks, chemical runoff, carbon emissions, and natural disaster vulnerability all fall into this category. Failure to manage environmental risks can lead to shutdowns, lawsuits, and permanent brand damage.

Psychosocial Risks:

Stress fractures more than bones—it fractures culture. Risks in this category include mental fatigue, toxic management behavior, burnout, and workplace harassment. These aren’t always visible on a checklist, but they show up in absenteeism, turnover, and disengaged teams.

Recognizing these risks early—and tracking them consistently—is the first step toward a safety strategy that actually works.

Key Components of Environmental Health Safety Risk Management

Here are the pillars of a high-performing EHS risk management program. Get these right, and you’re not just checking boxes—you’re building a culture that saves lives, avoids fines, and keeps operations running. A strong EHS program is built on these foundations:

EHS Policy and Objectives

This is your foundation—your public commitment to safety, environmental responsibility, and operational integrity. It’s more than a document—it’s a message from leadership that safety isn’t optional, it’s operational. Objectives should be clear, measurable, and tied directly to business outcomes: zero incidents, full compliance, reduced emissions, improved worker retention.

Hazard Identification Processes

Hazards must be identified where they occur—on the ground, in real time. Teams need streamlined systems to document unsafe conditions, using photos, notes, or voice memos, even when offline. Reports should be timestamped, geo-tagged, and routed to responsible personnel without delay. With Field1st, crews can log a cracked scaffold, leaking valve, or unsecured load instantly—using photos, voice memos, or a few quick taps, even with no internet. Each report is GPS-stamped and routed to the right person for action.

Risk Assessment Frameworks

Not all hazards are equal. Some need a bandaid, others need a shutdown. Risk assessment requires a structured approach to evaluating potential impact and likelihood. Use a standardized scoring matrix to prioritize corrective actions—ensuring critical issues are escalated quickly, and lower-risk items are scheduled accordingly.

Preventive and Corrective Controls

Every risk needs a response—whether it’s implementing physical barriers, updating SOPs, or issuing refresher training—each identified risk needs a clear, trackable response. With Field1st, once a hazard is logged, the system can automatically assign a CAPA (Corrective and Preventive Action), set a deadline, and track it to completion. Nothing falls through the cracks.

Employee Training and Participation

Knowledge is armor. Effective safety programs don’t just train workers—they engage them. Training should be role-specific, scenario-based, and refreshed regularly. Field1st delivers just-in-time learning, daily toolbox talks, and training log tracking—so your workforce is ready, not reactive. Better yet, it creates feedback loops so workers aren’t just trained—they’re heard.

Incident Reporting & Investigation Systems

When incidents happen, fast and structured response is critical. A good system enables instant logging of events, supported by media evidence, time stamps, and defined investigation workflows. Root cause analysis should lead directly to updates in training, controls, or procedures—closing the loop on every incident.

Monitoring, Audits & Continuous Improvement

Safety isn’t a one-and-done game—it’s a continuous cycle. Regular audits, both internal and external, provide checkpoints. Monitor both leading and lagging indicators to get ahead of potential issues. Use quarterly reviews to refine strategy, update controls, and demonstrate measurable progress across the organization.

Steps to Implement Environmental Health Safety Risk Management

Whether you’re launching a new EHS program or leveling up an existing one, these steps provide a field-proven path to risk control and compliance. And with a digital platform like Field1st, each of these steps becomes not just easier, but automatic, scalable, and built for the chaos of real jobsite conditions.

1. Identify Hazards

Effective risk management starts with seeing what could go wrong—before it does. That means encouraging frontline teams to capture hazards as they happen: a frayed wire, an unguarded ledge, an oil spill on the loading dock. Real-world awareness begins with real-time reporting.

Field1st equips crews to log hazards instantly—photos, notes, voice memos—even when offline or underground.

2. Assess Risk

Not every hazard requires the same level of response. Prioritization is key. Risk assessment frameworks evaluate how likely a hazard is to occur and how severe the impact would be if it does. This ensures that time and resources are aimed at what matters most.

Field1st helps apply structured risk scoring to every entry, with visual dashboards that highlight top threats at a glance.

3. Implement Controls

Once risks are understood, it’s time to eliminate or reduce them. This could mean removing a hazard entirely, engineering a safeguard, or instituting procedures and protective gear. Controls only work if they’re clearly assigned and tracked.

Field1st automates the assignment, scheduling, and escalation of CAPAs—ensuring nothing falls through the cracks.

4. Train Teams

Controls mean nothing if your people don’t understand them. Training should be risk-specific, role-based, and frequent enough to stay top of mind. It’s not just about compliance—it’s about confidence in the field.

Field1st delivers targeted training, toolbox talks, and microlearning directly to the right team members at the right time.

5. Monitor & Log

Once controls are in place, you need visibility into whether they’re working. That means tracking inspections, logging new hazards, and keeping an eye on CAPA close-out rates. Continuous monitoring gives you the pulse of safety performance.

Field1st provides real-time dashboards with filterable data across all projects, sites, and roles—making the invisible visible.

6. Review & Improve

Risk never sleeps, and neither should your program. Regular reviews of performance data, incident trends, and training effectiveness allow your EHS strategy to evolve with changing conditions. Improvement is an ongoing cycle—not a box to check.

Field1st supports periodic audits, generates historical reports, and helps teams refine strategies based on field data, not guesswork.

Best Practices for Environmental Health Safety Risk Management

A strong EHS strategy is built on habits. The right daily practices hardwire safety into your operations and keep your teams two steps ahead of risk. These aren’t just check-the-box tips. They’re field-tested tactics that separate reactive teams from proactive ones.

Empower Field Teams

The people closest to the hazards should be the first to act. That’s why it’s critical to give frontline workers the power to report what they see, without red tape or delays. Fast, intuitive reporting systems and anonymous submission options encourage full participation from every corner of the jobsite.

Digitize Everything

Paper logs get soaked in rain, lost in glove compartments, or forgotten in break rooms. Digital systems solve for that. Inspections, incident reports, and corrective actions should be logged, time-stamped, and stored securely—accessible from HQ to the jobsite, with full audit trails to back it up.

Post-Incident Reviews

Every incident is a data point. Every close call is a warning shot. Structured post-incident reviews are essential for identifying root causes, closing systemic gaps, and reinforcing lessons learned. The better the documentation, the sharper the insights—and the faster the improvements.

Track Leading Indicators

Injuries and violations are lagging indicators—they tell you something’s already gone wrong. Get ahead by tracking leading indicators: unsafe conditions, safety observations, near misses, and behavioral trends. These data points are your early warning system.

Standardize Risk Scoring

If every team uses different risk language, your data turns into noise. A standardized scoring matrix—based on likelihood and severity—helps teams consistently prioritize actions across sites, shifts, and regions. Clarity drives faster decisions and better coordination.

Tie Risk to KPIs

Safety performance is directly tied to productivity, cost control, and employee retention. When you link safety metrics to broader business KPIs—like uptime, project delays, or workforce engagement—you demonstrate safety’s ROI and bring executive teams into the conversation.

How to Streamline Risk Management

Field1st brings all these best practices under one roof. It empowers frontline crews with mobile tools to log hazards in real time—photos, notes, GPS tags, even offline. It digitizes your entire safety system, storing everything in a searchable, audit-ready cloud. Post-incident reviews are enriched with multimedia evidence. Leading indicators are tracked live through intuitive dashboards. Risk scoring is standardized across every site. And safety metrics are tied directly to business outcomes, turning EHS from a compliance task into a strategic asset.

6 Best EHS Risk Management Software (2025)

Choosing the right EHS risk management software can be the difference between reactive firefighting and proactive safety leadership. Whether you’re managing hazards on a construction site, in a manufacturing plant, or across multiple facilities, these platforms offer modern solutions tailored to different scales and needs. You have now seen a glimpse of how Field1st can support field teams. Now, let’s see how it compares with other software in the market. Here’s a breakdown of six top tools worth evaluating in 2025, starting with Field1st:

1. Field1st

Field1st is a mobile-first EHS platform built for frontline chaos.

Designed specifically for high-risk, field-heavy industries, Field1st empowers frontline crews to log hazards, close out CAPAs, and track training—even offline or underground. It combines customizable workflows, AI-powered tagging, and blazing-fast reporting to bring field reality into sharp digital focus.

What sets it apart: Built for chaos—offline-ready, AI-enhanced, and ruthlessly efficient. Whether it’s a muddy construction site or a wind-blasted turbine, Field1st was built to thrive in the mess—not just manage it.

While Field1st is built to dominate in complex, high-risk environments, its depth and field-first design may be more than what smaller teams or low-risk operations need. Simpler setups might find the platform’s power underutilized.

Best For: Construction, energy, manufacturing, and utilities.

2. SafetyCulture (iAuditor)

SafetyCulture is the go-to for structured inspections and templates.

iAuditor’s strength lies in its massive template library and intuitive inspection workflows. It’s perfect for teams with repeatable safety routines, strong connectivity, and minimal field variability.

Compared to Field1st: Great for checklists and routine audits, but struggles in high-variability, real-time field conditions due to limited offline capability.

Best For: Low-risk industries with stable environments and process repetition—like hospitality, retail, and offices.

3. Gensuite

Gensuite is a heavyweight built for enterprise complexity.

An enterprise-grade platform that covers everything from audits to ESG and compliance management. It’s incredibly deep but comes with a steep learning curve and a longer implementation timeline.

Compared to Field1st: Gensuite is great for compliance depth, but not optimized for rapid deployment or dynamic field environments.

Best For: Enterprises with large EHS teams, complex global reporting needs, and multiple sites.

4. EHS Insight

EHS Insight is the agile middleweight for growing teams.

Its modular setup means you only pay for what you need. It’s approachable, well-designed, and hits the sweet spot for companies scaling their EHS without a bloated toolset.

Compared to Field1st: Its mobile experience lags behind modern-first platforms, and it lacks some AI-driven capabilities.

Best For: Mid-market companies scaling up their EHS programs with 2–10 active sites.

5. VelocityEHS

VelocityEHS is a powerhouse in chemical and ESG compliance.

Its standout strengths are chemical tracking, environmental risk logging, and tight regulatory alignment. This is the tool you want if you’re neck-deep in MSDS sheets, EPA audits, or ESG mandates.

Compared to Field1st: It’s not built for real-time frontline responsiveness—more for back-office compliance managers and regulatory specialists.

Best For: Industrial, chemical, or environmental teams dealing with strict regulation.

6. KPA.io

KPA is a fast-launch solution for small teams.

Simple, pre-built, and ready to deploy—KPA gets small-to-midsize businesses up and running quickly. It includes reporting, templated training, and safety form libraries, with a clean user interface.

Compared to Field1st: Though it is great in speed and simplicity, it lacks flexibility and depth.

Best For: Small businesses or those building their first formal EHS system.

In 2025, the best EHS software isn’t just about features—it’s about the right fit for your team. For high-risk, field-driven industries like construction, energy, and manufacturing, platforms like Field1st deliver the control, speed, and visibility safety leaders need to lead from the ground up.

Environmental Health Safety Risk Management Starts with Field1st

Managing environmental, health, and safety risks is no longer about compliance alone. It’s about survival, reputation, and strategic growth. The companies that win in 2025 will be those that make EHS risk management part of their daily operations—not quarterly reports.

With Field1st, your team gets a platform that:

- Enables mobile inspections and hazard logging from anywhere

- Powers real-time reporting and alerts

- Automates corrective actions and escalations

- Supports role-based training and reviews

- Integrates easily across departments

Book a free demo to see how Field1st helps you lead with safety—from the field up.