From wellheads to pipelines, the oil and gas industry runs on pressure—both literally and figuratively. High temperatures. Explosive atmospheres. Remote locations. Massive machinery.

In this environment, risk isn’t a possibility, it’s a given. And a single misstep can cost lives, trigger environmental disaster, halt production, and rack up millions in fines, litigation, or lost contracts.

That’s why safety and risk management in the oil and gas industry isn’t just regulatory housekeeping—it’s a frontline business strategy. When done right, it fuels operational efficiency, reduces unplanned downtime, cuts insurance and injury costs, and reinforces environmental responsibility.

The operators who treat it as a performance lever—not a compliance chore—are the ones who stay ahead, stay profitable, and stay trusted.

In this guide, we’ll walk through:

- The core concept of risk management in oil and gas

- Why it matters beyond compliance

- The types of risks operators face

- Proven frameworks to manage risk

- 7 field-tested strategies to reduce incidents and improve safety culture

- How Field1st simplifies and strengthens every step of the process

Let’s get into it.

What Is Risk Management in the Oil and Gas Industry?

In the oil and gas sector, risk management refers to the systematic identification, assessment, and mitigation of potential hazards across exploration, drilling, production, refining, and transportation.

But this isn’t just about checking equipment or reporting near-misses. It’s about protecting lives, shielding the environment, and ensuring multi-billion-dollar operations don’t come to a grinding halt due to preventable failures.

The complexity of oil and gas environments—remote locations, high-pressure systems, flammable materials, and heavy machinery—requires layered, continuous risk oversight across every phase of operation.

Key goals of risk management include:

- Preventing accidents and injuries

- Complying with regulatory standards (OSHA, EPA, ISO)

- Reducing downtime and financial losses

- Avoiding environmental damage

- Safeguarding company reputation and stakeholder confidence

Today, forward-thinking operators are evolving from reactive risk management to proactive, tech-enabled systems that detect, predict, and prevent failures in real time. This shift is no longer optional—it’s mission-critical.

Why Safety and Risk Management Matter in Oil & Gas

The consequences of failure in this industry are catastrophic—explosions, environmental devastation, worker fatalities, lawsuits, shutdowns, and billion-dollar damage to brand equity. Here’s why smart companies make safety and risk management a strategic priority—not just a compliance task.

1. Protecting Worker Safety

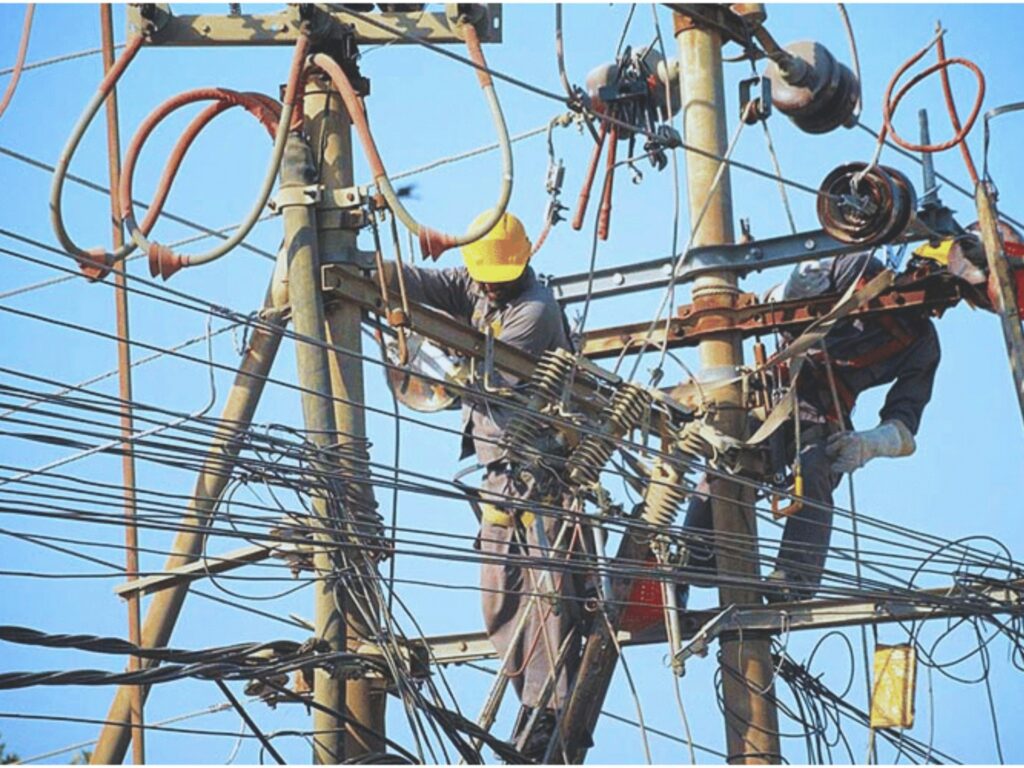

Whether it’s offshore rigs, inland refineries, or remote drilling pads, oil and gas work is inherently dangerous. Safety programs prevent falls, blowouts, toxic exposure, and equipment-related injuries through structured protocols, hands-on training, and proactive monitoring.

Complying with OSHA, API standards, and ISO 45001 isn’t just about avoiding fines—it’s about keeping people alive, every single shift. One mistake in a high-pressure zone can turn fatal in seconds.

2. Preventing Environmental Disasters

Spills, flares, gas leaks, and emissions can devastate ecosystems, communities, and company reputations. These events attract media attention, public outrage, and massive cleanup costs.

Effective risk controls help:

- Prevent pipeline ruptures

- Monitor pressure anomalies

- Ensure safe disposal of hazardous materials

- Track environmental impact across the supply chain

Risk management is environmental stewardship in action. And in today’s ESG-driven investment landscape, that stewardship directly impacts capital access and growth potential.

3. Ensuring Compliance and Avoiding Penalties

Violating safety and environmental regulations can trigger:

- Hefty OSHA fines

- EPA lawsuits

- Shutdown orders

- Loss of operating licenses

- Blacklisting from high-value contracts

Proactive risk management keeps your company audit-ready, protected, and off government radar—because you’re already doing things by the book, and then some.

4. Reducing Downtime & Financial Losses

Unexpected shutdowns can cost millions per day—especially in midstream or offshore operations. But many shutdowns are preventable.

A strong safety program reduces:

- Equipment failure from neglect

- Fire damage from poor hazard tracking

- Labor disruptions due to unsafe working conditions

Every avoided incident is a financial win that protects margins and project timelines.

5. Building Trust with Stakeholders

Investors, employees, clients, regulators—their eyes are always on your operations. What they’re really watching is your TRIR, your audits, and your response to risk.

A proactive safety record builds confidence. A single high-profile failure can erase decades of goodwill and cost your company future contracts.

Reputation is your most fragile asset—protect it with process, consistency, and tech-enabled transparency.

Types of Risks in the Oil and Gas Industry

Not all risks are created equal—and in oil and gas, even the low-probability ones can carry massive consequences. Understanding and categorizing risk is the first step in managing it.

Operational Risks

These are the most immediate and visible threats to life, equipment, and uptime:

- Fire and explosion risks due to flammable gases or volatile environments

- Toxic gas exposure like H2S leaks—fast-acting and often deadly

- Slips, trips, and falls in wet decks, uneven terrain, or icy platforms

- Well blowouts from poor pressure control, especially in deep wells

- Equipment failure from metal fatigue, poor maintenance, or substandard components

- Human error from fatigue, distraction, or insufficient training

Operational risks demand constant vigilance, digital inspections, and real-time issue reporting—exactly where platforms like Field1st provide frontline value.

Environmental Risks

Environmental failures aren’t just expensive—they’re public.

- Oil spills from ruptured pipelines, tankers, or offshore rigs

- Emissions from flaring, venting, or uncontrolled gas releases

- Waste disposal failures that poison local water and soil supplies

- Habitat destruction from poorly managed site expansion

These risks often result in government crackdowns, long-term remediation costs, and irreparable brand damage.

Regulatory & Compliance Risks

Falling out of compliance can shut down entire operations.

- OSHA citations from failed inspections

- EPA enforcement for emissions or spill violations

- Failure to meet ISO 45001 or 14001 standards

- Lapses in local drilling permits or environmental assessments

Often it’s not gross negligence—it’s paperwork delays, missing documentation, or disconnected systems. Field1st eliminates that chaos with timestamped, audit-ready records.

Financial Risks

Safety and financial health are directly linked.

- Market volatility impacting material costs and project timelines

- Geopolitical events disrupting exports or access to key sites

- Supply chain delays for critical parts and safety gear

- Skyrocketing insurance premiums for high-incident operators

- Cost of emergency response teams, repairs, and lawsuits

The more unsafe your operation, the more every dollar is at risk.

Reputational Risks

In 2025, one leaked video of a flare-out, injury, or explosion can go viral within hours—and tank public trust.

Reputational risk isn’t theoretical—it’s a bottom-line reality. Contracts are lost. Partners walk away. Investor relations collapse.

Today, companies must not only be safe—they must be seen actively proving it. Tools like Field1st help document safety actions in real time, providing transparency and building trust long before an incident ever occurs.

Proven Risk Management Frameworks for Oil & Gas

You don’t have to guess—global, field-tested frameworks exist to structure your safety and risk management programs. They provide a common language, consistent process, and measurable goals to keep everyone aligned—from the jobsite to the boardroom.

ISO 31000: Risk Management Framework

- Internationally recognized standard

- Focuses on integrating risk into all decision-making levels

- Emphasizes transparency, accountability, and governance

- Promotes continuous improvement through data-driven feedback loops

Use ISO 31000 as a blueprint to align field-level practices with corporate risk strategy—ensuring consistency across regions, divisions, and partners.

Bowtie Analysis: Visual Risk Mapping

- Helps teams visualize the chain from cause to consequence

- Splits risks into preventive and reactive controls (barriers)

- Clear for both technical teams and non-technical stakeholders

- Great for toolbox talks and risk communication in the field

Bowtie analysis turns abstract threats into visible, fixable risks—making risk real and manageable.

HAZOP (Hazard and Operability Study)

- Deep dive review of processes and system behavior

- Identifies design, logic, or human-factor flaws before they surface

- Commonly used during design, commissioning, and operational phases

- Requires collaboration across disciplines

When paired with Field1st’s mobile audit tools, HAZOP becomes faster to deploy, easier to document, and more actionable—across every jobsite.

7 Strategies for Better Safety and Risk Management in Oil & Gas

These are the strategies used by leading operators to lower incident rates and boost operational resilience.

1. Comprehensive Risk Identification & Profiling

Every site has different risks—from Arctic pipelines to Gulf Coast platforms. Conduct site-specific assessments, review historical data, assess equipment integrity, and factor in workforce experience, turnover, and exposure levels.

Field1st enables digital profiling of each location, allowing HSE teams to log, tag, and prioritize risks dynamically. Its real-time dashboard makes it easy to spot emerging threats before they escalate into recordables—ensuring nothing gets missed, even across complex, multi-site operations.

2. Proactive Hazard Mitigation Plans

Reactive safety doesn’t cut it. Build mitigation into your daily workflows.

- Create JHA-based controls

- Use automated alerts for pressure spikes or high-risk tasks

- Track open hazards across shifts

- Escalate unresolved issues to leadership automatically

With Field1st, hazard tracking is automatic. Teams receive real-time push alerts, field crews can log issues instantly, and supervisors gain full visibility on status updates—ensuring nothing slips through the cracks, no matter the shift or site.

3. Workforce Training & Emergency Preparedness

Training isn’t just for onboarding—it’s ongoing.

- Run drills for spills, fires, and gas leaks

- Use real-life case studies in training sessions

- Offer multilingual materials and visual guides

- Ensure every worker knows their emergency role

- Reinforce procedures with job-specific micro-learning modules

Field1st integrates with mobile learning tools, allowing workers to complete safety briefings, certifications, and training refreshers from their devices—even offline. Whether in the field, on a rig, or between shifts, training stays accessible, consistent, and trackable.

4. Compliance & Safety Standards Adherence

You don’t just have to comply—you have to prove it.

- Maintain OSHA 300 logs

- Document safety meetings, inspections, and incident responses

- Keep all records audit-ready and version-controlled

- Centralize documentation for multi-site visibility

Field1st automates this. It creates time-stamped digital logs, stores training, inspection, and corrective action data, and lets you generate audit-ready compliance reports in seconds—no paper chasing, no missing files, no surprises when the inspector shows up.

5. Environmental Risk Management & Sustainability

Environment-focused safety is both ethical and strategic.

- Monitor emissions with IoT sensors

- Track waste handling from cradle to grave

- Prevent spills with pressure, corrosion, and leak detection tools

- Log environmental impact events and corrective actions in real time

Investors are watching your ESG performance. Field1st helps you log, track, and report environmental safeguards as part of your core safety operations—turning environmental responsibility into measurable, auditable, and reportable proof that you’re building a sustainable operation, not just saying it.

6. Leverage Technology for Risk Mitigation

Enhanced by Field1st

- Use IoT for equipment monitoring

- Apply AI for predictive maintenance alerts

- Use digital twin models to simulate risk events

- Track incidents in real-time and flag trends early

- Set automated triggers for corrective workflows

Field1st combines mobile data collection with analytics—so you can monitor leading indicators, flag high-risk behaviors, and respond before a near-miss becomes a headline. It shifts your team from reactive firefighting to predictive, data-backed decision-making—scaling safety across every asset, crew, and shift.

7. Build a Strong Safety Culture

Policies are just paper without buy-in.

- Empower field crews to report hazards anonymously

- Recognize safe behavior publicly

- Involve supervisors in safety planning and daily safety huddles

- Promote accountability from the C-suite down with measurable safety KPIs

- Embed safety values into hiring, onboarding, and performance reviews

Safety has to be everyone’s job. Technology like Field1st makes it easier to communicate, measure, and reinforce that culture every day—ensuring safety isn’t a slogan, but a shared, lived behavior at every level.

Smarter Safety Starts with Field1st

Oil and gas will always be risky—but your response doesn’t have to be.

The companies that thrive in 2025 and beyond will be those who embed risk management into daily operations—from morning safety briefings to boardroom dashboards. That requires more than policy. It requires real-time visibility, automation, and execution.

Field1st is the tool built to support that shift.

- Site-specific risk profiling

- Real-time incident tracking

- Audit-ready compliance reports

- Predictive hazard detection

- Embedded training and emergency protocols

- Field-first, mobile-friendly, and offline-capable

- Scalable across regions, rigs, and contractors

If you’re still managing safety with clipboards, disconnected apps, or post-incident reports—you’re not just behind. You’re exposed. Field1st helps teams close the gap between risk and response—permanently.

Ready to Make the Shift?

Let Field1st help you build a smarter, safer oil and gas operation—one that protects people, protects the planet, and protects your bottom line.

See Field1st in action

Your future depends on what you do today. Start managing risk like it matters—because it does.