You can’t fix what you don’t see. That’s the core of safety observations in high-risk industries. When someone logs a hazard in the field—whether it’s a missing guardrail, an oil spill, or a near miss—they’re not just checking a box. They’re giving your team a shot to act before things go wrong.

Workplace safety is shifting fast. With OSHA fines climbing and ESG expectations growing, companies can no longer afford to rely on scattered paper forms or post-incident reporting. Studies show that every $1 invested in proactive safety can save $4 to $6 in potential incident costs. That’s not just compliance, that’s smart business.

This guide breaks down what a safety observation report is, why it matters, and how you can use it to build a safer, smarter operation. You’ll learn exactly what to document, how to document it, and how a mobile-first platform turns everyday observations into your strongest tool for risk prevention.

What is a Safety Observation?

A safety observation is a real-time review of workplace behavior or conditions that could affect health and safety. In fact, consistent safety observations in the workplace are one of the most effective ways to identify risks before they escalate into recordables, violations, or worse. Think of it as an early warning system—something you catch before it turns into paperwork, injury, or worse. It can be formal (logged with photos and severity ratings) or informal (a verbal heads-up to a coworker).

They’re typically conducted by:

- Safety officers or EHS managers

- Site supervisors or foremen

- Trained field employees

And they matter most in industries where the cost of “waiting to report” is too high:

| Industry | Application | Benefits |

|---|---|---|

| Construction | Monitoring compliance with safety protocols on active job sites. | Reduces accidents, flags near misses, and helps stay ahead of OSHA violations. |

| Manufacturing | Conducting observations during machine operations, line inspections, or shift changes. | Prevents equipment misuse, identifies unsafe behaviors, and reduces production stoppages. |

| Oil & Gas | Detecting hazards in rig zones or refineries, especially in high-risk environments. | Enables faster intervention and reduces the risk of catastrophic incidents. |

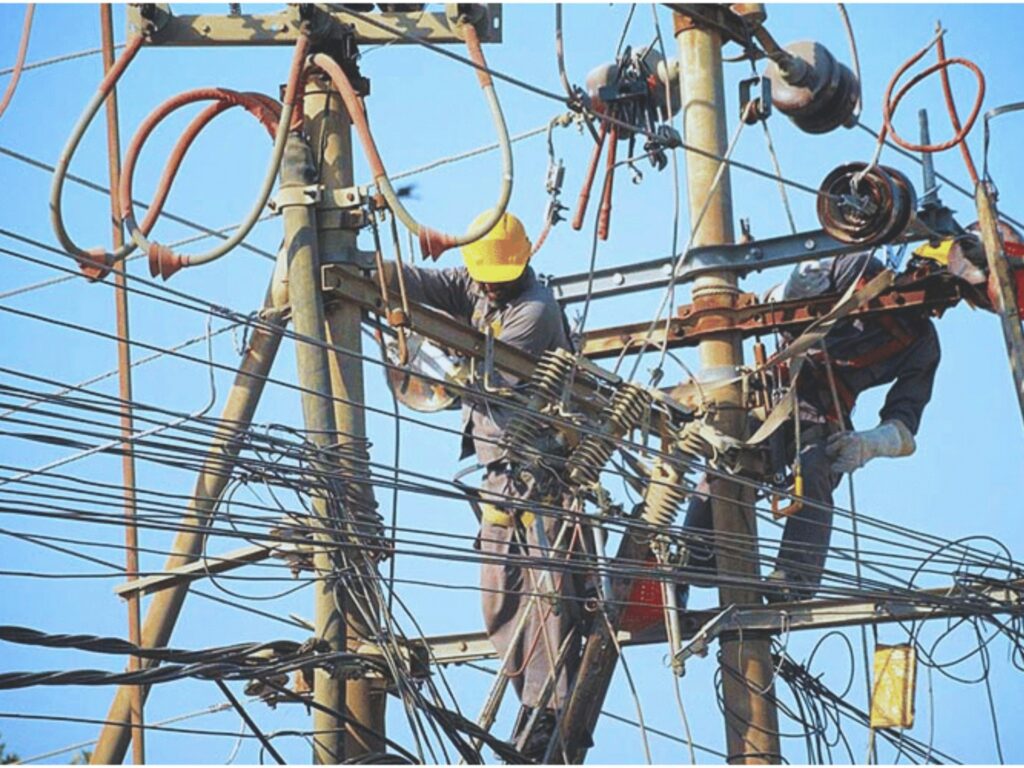

| Utilities | Documenting site conditions, electrical risks, and infrastructure issues in the field. | Improves injury prevention and ensures compliance with environmental and safety standards. |

| Logistics & Transportation | Observing vehicle operations, loading dock procedures, and warehouse activity. | Decreases worker injuries and improves fleet safety performance. |

The goal? Spot potential risks before they escalate—and close the loop before someone gets hurt.

Related Read: Safety Observation Software

What is a Safety Observation Report?

A safety observation report documents the findings of a safety observation. It captures key details: what was seen, where it happened, when it occurred, and what needs to be done.

Safety observation reports help with:

- Tracking recurring hazards across locations or shifts

- Reporting to regulatory bodies like OSHA, ISO, or local authorities

- Assigning and verifying corrective actions

Done right, these reports become a living record of your team’s safety awareness. And with digital platforms like Field1st, those records are instantly accessible, searchable, and actionable.

Key Benefits of Conducting Safety Observations

Safety isn’t just about responding to incidents—it’s about staying five steps ahead of them. Regular safety observations give your team the power to spot problems before they become headlines, lawsuits, or worse. Whether it’s a loose railing, an overlooked procedure, or a near-miss that could’ve been deadly, observations are how you stay sharp, proactive, and in control.

Below are five key benefits of safety observations:

1. Fewer Accidents and Injuries

Most incidents don’t come out of nowhere. There’s always a warning sign—if someone’s watching. Safety observations catch those signs early: a broken harness, blocked exit, missing signage. When your crew is trained to look—and has an easy way to log what they see—you stop incidents before they start. It’s not just about compliance. It’s about keeping people alive.

2. Better Regulatory Compliance

When OSHA shows up or a client asks to see your safety logs, you don’t want to scramble. You want a clean, digital paper trail—complete with timestamps, signatures, follow-ups, and documented corrections. Field1st gives you exactly that. Every observation is logged, auto-versioned, and locked into place—ready for auditors, inspections, or that surprise drop-in from the safety committee.

3. Cost Savings

Every injury avoided saves you money. We’re talking direct costs like medical bills and equipment damage—and indirect ones like downtime, insurance hikes, and legal exposure. Proactive safety observations keep little problems from turning into six-figure disasters. It’s one of the few places where time spent upfront pays off tenfold down the line.

4. Early Hazard Detection

Seeing one ladder left unsecured is a fluke. Seeing it five times in a week? That’s a trend. With Field1st, safety leaders can spot patterns across teams, sites, or shifts—before those patterns lead to a serious event. Dashboard analytics and smart tagging turn raw data into real-time insight, giving you the power to act early and decisively.

5. Higher Employee Engagement

When workers know their voices matter—that their observations don’t just disappear into a spreadsheet—they start paying closer attention. They speak up more. They take ownership. Over time, that creates a culture where safety isn’t just a checklist—it’s a shared mission. And that kind of buy-in? It’s priceless.

10 Most Common Safety Observation Examples

You don’t need a major accident to know something’s off. In fact, the most valuable data in your safety program often comes from the small stuff—the day-to-day missteps and overlooked conditions that silently stack up into real danger.

That’s where safety observations come in. By documenting both unsafe acts and conditions, you create a living, breathing risk map of your worksites. Below are 10 of the most common safety observations teams encounter—divided into two key categories: human behavior and environmental hazards. Train your teams to spot these, and you’re not just reacting to incidents… you’re preventing them.

Unsafe Acts

These are behaviors—what people do (or don’t do)—that raise risk in real time.

- Skipping PPE. Hard hats tossed aside, gloves missing, goggles dangling—when protective gear becomes optional, injuries become inevitable. Logging these lapses helps reinforce habits that save lives.

- Improper Lifting or Ergonomics. Twisted backs, overloaded arms, awkward reaches. One bad lift can lead to weeks off the job. Observing and coaching this early prevents compounding injuries.

- Unsafe Equipment Use. Untrained hands on heavy machinery, damaged tools in rotation, or power tools used one-handed. These moments are where small mistakes turn into severe outcomes.

- Ignoring Emergency Procedures. Skipping fire drills, blocking exits, fumbling during mock evacuations—if emergency procedures aren’t followed during drills, they won’t be followed under pressure.

- Taking Shortcuts. Whether it’s bypassing lockouts, rushing through safety checks, or “just this once” behavior—shortcuts often lead straight to incident reports. Behavior-based observations catch these before they become habits.

Unsafe Conditions

These are environmental issues—the physical setup of the workspace—that could lead to harm.

- Blocked Exits. A forklift parked in front of an emergency door. Pallets in the escape path. These are more than violations—they’re potential death traps in a fire or chemical leak.

- Slippery Surfaces. Rain tracked in, oil spills, condensation on smooth flooring. Slip hazards are one of the most common—and preventable—causes of workplace injuries.

- Unprotected Heights or Fall Hazards. No guardrails, missing toe boards, exposed edges. Fall risks don’t forgive. Observing them, documenting them, and fixing them can prevent the worst-case scenario.

- Exposed Wiring or Electrical Hazards. Frayed cords, overloaded outlets, temporary setups that become permanent. These aren’t “minor maintenance issues”—they’re waiting to start a fire or shock someone badly.

Near Misses. A scaffold sways but doesn’t fall. A forklift clips a rack but doesn’t tip it. These moments are gold—because they give you a chance to fix the root cause before someone ends up in the ER.

Key Elements of a Safety Observation Report

A good safety observation report doesn’t just tick boxes—it tells the full story of a risk before it becomes an incident. It should capture exactly what happened, where it happened, who saw it, and most importantly—what needs to happen next.

Whether you’re walking a job site, inspecting a warehouse, or responding to a near miss, your ability to log what you see clearly and consistently is the frontline defense of your safety program. These key elements form the backbone of a reliable, actionable observation report—especially when paired with tools like Field1st, which makes capturing and escalating them fast, mobile, and audit-proof.

Here’s what every safety observation report should include:

1. Observer Name

Who logged the observation?

Accountability starts with attribution. Whether it’s a foreman, safety officer, or crew lead, recording the observer ensures clarity—and builds trust in the data.

2. Date & Time

When was the observation made?

Time-stamping the moment you caught a hazard helps track patterns—whether it’s repeated infractions on the night shift or seasonal risks tied to weather.

3. Location

Where exactly did this happen?

A vague “warehouse floor” won’t cut it. You need room numbers, zones, jobsite sections—anything that helps someone act fast.

4. Description

What did you see, and what made it unsafe?

This is the meat of the report. The more detail, the better. Was it a trip hazard from loose cables? A worker bypassing a guard? Describe what triggered the concern. Field1st supports voice-to-text entries, so teams can describe issues naturally, even when typing’s not an option.

5. Severity Rating

How serious is the risk?

Categorizing the issue helps prioritize action. Use terms like Low, Moderate, or High—or a numerical scale if your organization prefers.

6. Corrective Actions

What needs to happen next—and who owns it?

This turns a report into a resolution. Maybe it’s a quick clean-up, maybe it needs an engineering fix. In Field1st, you can assign corrective actions instantly, add deadlines, and set escalation rules if no one acts. No more wondering “Did this ever get fixed?”

7. Evidence

Got photos or video? Use them.

A blurry write-up can leave room for doubt—but a photo speaks volumes. Use visuals to show the hazard, context, or resolution. Field1st makes it easy to snap and attach media on the spot, even when offline. Everything’s time-stamped and stored automatically, so you’re always audit-ready.

Pro Tip: Want to go from reactive to proactive? Review your observation reports regularly to spot trends. That’s where Field1st dashboards shine—filtering issues by site, crew, severity, or timeframe to show what’s improving… and what’s not.

How to Make a Safety Observation Report (Step-by-Step)

A powerful job safety observation isn’t just about what you see—it’s about what you do with it. Every incident avoided, every hazard caught early, starts with someone speaking up and logging what they saw. That’s what makes safety culture real. But let’s be honest—most teams don’t need more forms. They need a faster, easier way to record what matters before it slips through the cracks.

This is where a clean, repeatable observation process comes in—especially when powered by tools like Field1st, which was built to move at jobsite speed. Whether you’re logging near misses, bad lighting, or unsafe equipment use, here’s how to turn a moment of awareness into a documented, trackable, and resolved action.

1. Identify and Document the Observation

First, catch it before it causes harm.

Did someone skip their PPE? Was equipment damaged, or was a spill left unchecked? This is the moment to log the issue—not later, not after your shift, and definitely not “when you get to a computer.”

With Field1st, observations can be captured in real-time, even mid-shift, using mobile-first tools that work offline and don’t slow you down.

2. Capture Supporting Evidence

A picture isn’t just worth a thousand words, it could be the difference between a warning and a fix.

Snap a photo, record an audio note, or even film a short video. Evidence makes your observation more credible, clear, and audit-ready. Field1st lets you upload media on the fly, all auto-tagged with location, time, and author.

No Wi-Fi? Field1st stores it anyway—then syncs when you’re back.

3. Assign Risk Severity

Not every hazard carries the same weight.

Classifying the risk helps safety leads prioritize fast. Is it a low-risk annoyance, a moderate issue, or a high-risk threat?

Field1st simplifies this with customizable dropdowns and even AI-driven suggestions based on past entries. So even new team members can classify accurately.

4. Recommend Corrective Action

Here’s where awareness turns into impact.

Once the issue’s logged, suggest the fix. Maybe it’s signage. Maybe it’s retraining. Maybe it’s calling in maintenance ASAP.

In Field1st, corrective actions can be auto-assigned, with clear owners, due dates, and escalation rules if nothing happens. No one can say, “I didn’t know.”

5. Submit for Review

Get it in front of the right people—fast.

Once your observation’s documented, it needs to reach the safety lead, supervisor, or site manager who can act. Field1st automatically routes the report to the right reviewer based on site, department, or severity—so nothing slips through the cracks.

6. Track Resolution

Because “submitted” isn’t the same as “solved.”

A real observation process ends in action, not just a spreadsheet.

With Field1st, every logged observation enters a dashboard workflow—so you can see when it’s acknowledged, when action is taken, and when the loop is fully closed. No more chasing updates. No more loose ends.

Pro Tip: Build the habit. When your crew knows observations are taken seriously, acted on quickly, and followed through to resolution, they’ll speak up more—and that’s how real safety culture spreads.

Manual vs. Digital Safety Observation Reports

Still using paper for safety observations? Here’s what you’re missing—and why switching to a digital system like Field1st doesn’t just make things easier, it makes them actually get done.

| Feature | Manual (Pen & Paper) | Field1st (Digital) |

|---|---|---|

| Offline Functionality | No access without forms | Full offline support, auto-syncs later |

| Evidence Capture | Limited to written notes | Photos, voice notes, video uploads in seconds |

| Auto CAPA Assignment | Needs manual follow-up | Instantly assigns actions + sends alerts |

| Audit Readiness | Manual sorting, error-prone | Auto-versioned, timestamped, audit-ready |

| Trend Reporting | Spreadsheet exports | Real-time dashboard analytics |

| Team Adoption | Low (tedious, slow) | High (mobile-first, 2-tap input) |

Transform Your Safety Observation Reports with Field1st for Faster, Smarter Risk Prevention

Safety starts with what your team sees—but it ends with what your system does with that info.

Manual reporting slows everything down. Opportunities slip through the cracks. CAPAs get lost in email threads. And by the time leadership sees the trend, it’s already too late.

Field1st flips that.

Observations go from handwritten notes to real-time data. Hazards trigger action instantly. Your team doesn’t just stay compliant—they stay ahead.

Book a demo of Field1st today and see how smarter safety observations can lead to a safer job site tomorrow.